American Plastics LLC Midland: Streamlining Your Plumbing and Construction Projects

Wiki Article

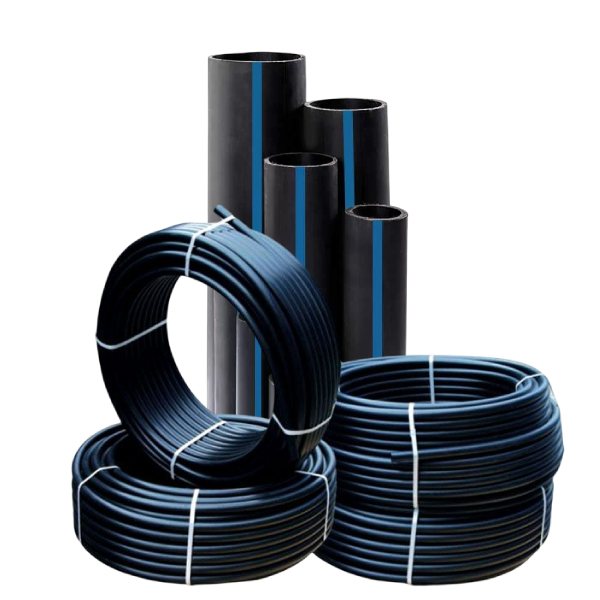

Locate the Perfect Pipe Products for Every Application in Your Market

Choosing the appropriate pipeline products is a vital job for any market. Numerous products serve distinct functions, and the selection can greatly impact effectiveness and safety and security. It calls for careful consideration of aspects like dimension, application demands, and conformity with regulations. Comprehending these aspects will certainly lead professionals in making informed decisions. As they navigate these complexities, the concern remains: how can one ensure they are selecting the very best alternatives readily available?Understanding Different Pipe Materials

When selecting pipe supplies for various applications, comprehending the distinctions amongst pipeline products is crucial. Each kind of pipeline product supplies one-of-a-kind residential properties and advantages fit for certain usages. For example, PVC pipes are lightweight, corrosion-resistant, and affordable, making them optimal for domestic plumbing and irrigation systems. On the various other hand, CPVC pipelines can endure higher temperature levels, making them ideal for warm water applications.Metal pipelines, such as copper and galvanized steel, are recognized for their durability and strength, usually utilized in industrial settings. Copper is additionally resistant to corrosion and has antibacterial homes. In contrast, steel pipelines are preferred for their effectiveness in high-pressure systems. Additionally, polyethylene pipelines are immune and flexible to chemicals, commonly made use of in gas and water distribution. Inevitably, the option of pipe product considerably impacts the performance, durability, and safety and security of the designated application, necessitating cautious consideration by market professionals.

Examining Size and Specs

Selecting the proper size and specs for pipeline materials is crucial for ensuring ideal performance in any kind of application. The length, size, and wall surface density of pipes directly affect their ability to deal with liquid circulation and pressure. It is vital to match these dimensions to the requirements of the system in which they will certainly be made use of. Standard sizes are commonly available, however custom-made requirements may be needed for specialized applications.In addition, the requirements ought to include factors to consider such as product compatibility, temperature tolerance, and pressure scores. These variables help ensure and stop failings long life. Properly assessing size and specs not only improves operational effectiveness however likewise lessens expenses related to product waste and system downtime.

Inevitably, a thorough understanding of the required size and specifications enables industries to make informed selections, bring about effective installments and trustworthy efficiency in their particular applications.

Examining Application Demands

How can one guarantee that pipeline products satisfy the particular needs of an application? The very first step involves a complete understanding of the operational setting (American Plastics LLC HDPE Pipe Supplier). Factors such as temperature level changes, pressure degrees, and exposure to corrosive materials have to be very carefully thought about. Next, the desired use of the pipes plays a critical duty; whether they are implied for transferring solids, liquids, or gases can significantly influence product selectionIn addition, the compatibility of pipe products here with the fluids being delivered is necessary to assure durability and performance. It is additionally recommended to consult industry requirements and regulations that might determine particular requirements for products and construction methods. Ultimately, looking for input from knowledgeable professionals in the field can give important understandings. By carefully evaluating these application demands, one can with confidence select pipeline products that not only fit however succeed in their designated duties, enhancing effectiveness and integrity in operations.

Thinking About Expense and Accessibility

Price and availability are vital variables that influence the choice of pipeline products for any kind of application. Businesses should examine their financial restraints you can look here while ensuring they have accessibility to the needed products (American Plastics LLC Texas). Higher-quality pipelines might feature boosted prices, yet they usually offer improved resilience and longevity, which can justify the investment graduallyAdditionally, the accessibility of details pipeline products can vary significantly based on place and provider connections. Business must create a reliable network of distributors to assure that they can resource materials without delay and prevent job delays.

Additionally, fluctuations in market need and worldwide supply chain problems can impact both price and schedule. Therefore, it is vital for industries to remain notified about market fads and preserve flexibility in their supply chain approaches. Inevitably, a well-considered method to cost and accessibility will boost operational performance and task success.

Guaranteeing Conformity and Safety Requirements

To navigate these complexities, firms must carry out detailed research on applicable criteria such as ISO, ASTM, and ASME. Teaming up with vendors that prioritize compliance can simplify the option process, ensuring that all pipeline supplies fulfill requisite accreditations. Regular audits and evaluations better improve safety and security by determining possible risks or shortages in materials. By focusing on compliance and safety and security, services not just safeguard their labor force but likewise improve their functional efficiency and track record within the industry. As a result, choosing the appropriate pipeline supplies is an essential action towards achieving a risk-free and certified functioning atmosphere.

Frequently Asked Inquiries

What Are the Best Brand Names for Pipe Materials in My Industry?

Leading brand names for pipe products consist of PVC, Victaulic, and Mueller. Their track about his record for toughness, innovation, and considerable product ranges makes them popular selections throughout numerous markets, ensuring trustworthy efficiency and top quality in pipeline applications.

Just how Do I Maintain Pipes to Make Certain Long Life?

To keep pipelines for durability, normal evaluations, cleaning, and proper sealing are vital. Furthermore, preventing extreme temperatures and using safety coverings can avoid corrosion, inevitably expanding the life-span and effectiveness of the piping system.What Tools Are Important for Pipe Installment?

Necessary devices for pipe installment include monkey wrench, cutters, installations, a level, gauging tape, and a blowpipe. These tools promote accurate measurements, safe and secure connections, and overall performance, making sure a successful pipe installation process.Can I Customize Pipeline Materials for Specific Projects?

_-_Post_di_Facebook_-_Dimensioni_personalizzate_(1)_60cafdf20856f.png)

Where Can I Discover Expert Suggestions on Pipeline Selection?

Professional advice on pipeline selection can commonly be found with industry-specific forums, maker representatives, and expert profession associations. In addition, specialized sites and neighborhood suppliers often supply examinations to aid guide finest selections for specific tasks.When selecting pipe materials for various applications, comprehending the distinctions amongst pipe materials is necessary. Selecting the suitable dimension and requirements for pipe materials is necessary for guaranteeing perfect efficiency in any kind of application. How can one guarantee that pipe materials fulfill the specific demands of an application? Guaranteeing compliance with guidelines and safety and security standards is critical in the choice of pipeline products for numerous applications. Essential tools for pipe installation include pipe wrenches, cutters, fittings, a degree, gauging tape, and a soldering iron.

Report this wiki page